Skip to content

AEROSPACE AND DYNAMIC SERVICESfscop622022-09-28T23:57:53+00:00

Meet your robust and ultimate targets with us through Quality, cost, and time savings.

AEROSPACE AND DYNAMIC INDUSTRIES

AEROSPACE AND DYNAMIC INDUSTRIES

We provide advanced technological auditing, Inspections, and compliance services. Performing Audits, Inspections, compliance surveys, Surveillance, Process improvements, Support Analytic Studies, Supplier chain, and Project Management Services.

INSPECTION SERVICES

-

Final Inspection

Inspection is performed in the final stage of the manufacturing process, and it is extremely important as it ensures that no major changes or damage to the property has occurred before shipment

-

Source Inspections – Product third-party shipment

Inspection is used to check the conformity of a product or assembly before it’s shipped to the purchaser. With the use of a source inspection, you can prevent issues later in the value stream by making sure the product is conformal to the supplier.

-

First Article Inspections per AS9102

Inspection is performed to assess the process of planning, manufacturing, and verifying a production process. A First Article Inspection Report (FAIR), is a document at the end to certify that each sample was produced and inspected according to the customer’s specifications

-

Borescope Inspections

An optical visual inspection that can examine hard-to-reach or inaccessible components without taking them apart or damaging them

-

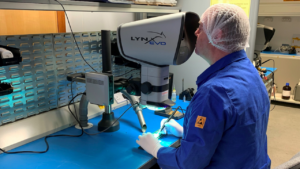

Pre-Cap & IPC 610/620 – J STD Inspections

This is a visual inspection of electrical or electronic components prior to package sealing. The process is a fast, non-destructive method of assuring a minimum level of reliability by segregating or removing devices with obvious defects from a population. This inspection is preferred to satisfy high reliability in electronic requirements that demand very high consistent results

-

In–Process Inspection

Inspection is performed at any point along the production cycle. This is done to check the parameters within each section of the process and whether they are in accordance with customer or industry requirements or specifications

DEVELOPMENT & PREPARATION AUDITING SERVICES

-

INTERNAL QUALITY AUDIT per Customer criteria/requirements

A systematic and independent examination of the supplier’s management perform to verify that the established quality system is operating effectively and as planned, and to determine the adequacy of the system to achieve the objectives; Process, Product, and System audit

-

AS 9100 PREP. AUDIT – Aerospace Quality Management System

AS9100 certification defines the design and manufacturing of standard aerospace products including parts, components, assemblies, and services. It is a widely adopted and standardized quality management system for the aerospace industry

-

PROCESS EFFECTIVENESS ASSESSMENT REPORT (PEAR) AUDIT

This audit process is used to methodically evaluate and states results while providing evidence of determining the effectiveness of a process based on the organization’s method for monitoring and measuring processes.

-

AS 9003 PREP. AUDIT – Inspection and Test Quality Systems

AS9003 standard specifies Inspection and Test Quality Systems Requirements for Aviation, Space, and Defense Organizations. This standard has less stringent requirements compared to AS9100, and its intent is to define a quality inspection system, not a quality management system.

-

ISO 9001 PREP. AUDIT – Generic Quality Management Systems

ISO 9001 standard sets out the requirements for a quality management system. It helps businesses and organizations to be more efficient and improve customer satisfaction.

-

AC 7004 PREP. AUDIT – Nadcap Aerospace Quality Systems

This is the Performance Review Institute (PRI) Nadcap Aerospace Quality Management System created to help small businesses with under 100 employees compete in the aerospace arena with the performance of special processes and still be on the same playing field as much larger manufacturers, without incurring the high cost of maintaining a quality system.

-

ISO 27001 PREP. AUDIT – Information Security Management System

ISO 27001 Certification is a business differentiator and demonstrates to other businesses they can trust your organization to manage valuable third-party information assets/data and intellectual property; this fosters a wealth of new opportunities whilst protecting your business from exposure to risk. Shows commitment to continual improvement, development, and protection of information assets/sensitive data by implementing appropriate risk assessments, appropriate policies, and controls.

-

ISO 14001 PREP. AUDIT – Environmental Management System

It maps out a framework for the formulation and maintenance that a company or organization can follow to set up an effective environmental management system. This helps to control your environmental aspects, reduce impacts, and ensure legal compliance.

-

ISO/IEC 17025/ ANSI/NCSL Z540. 3-20061 PREP. AUDIT Testing and Calibration

ANSI/NCSL Z540. 3-20061 calibration of measurement and test equipment (M&TE) is the American national standard used to improve Test accuracy by reducing measurement uncertainty. ISO/IEC 17025 enables laboratories to demonstrate that they operate competently and generate valid results, thereby promoting confidence in their work both nationally and around the world.

-

DIGITAL PRODUCT DEFINITION (DPD) APPROVAL PREP. AUDIT – Boeing D6-51991; Lockheed SQBMP13800; ULA QS-702.03; Northrop Grumman SQARUP-0100 Standards

Digital Product Definition (DPD) / Model Based Definition (MBD) audit verifies that procedures are established in the Quality Assurance Plan that identifies how control of digital data is maintained from receipt through end item acceptance. This is accomplished by accessing Basic Digital Product Definition (DPD), Model Based Definition (MBD), Coordinate Measurement System (CMS), and Plotter capability verifications. Digital product definition or DPD is digital data that specify the 3D CAD geometry and design requirements for a product DPD data known as product manufacturing information (PMI) includes manufacturing data for building and measuring a part, therefore, shifting from a 2D drawing workflow to a 3D CAD model-based workflow. Data from the 3D CAD model + PMI is used for driving interoperability throughout the product lifecycle and software including CAD, CAM, and CMS. DPD is also known as model-based definition or MBD.

-

SPECIAL PROCESS AUDITS; –

Special processes include procedures that alter or change the mechanical, chemical or physical parts of products within the operation or process, they require rigorous, standard-specific practices as well as qualified personnel or employees. Regulatory and quality system requirements state that every process that cannot be verified by subsequent monitoring or measurement shall be validated. If you can’t confirm the output with a direct test or measurement of the product – then you have a “special process” and must validate.

-

Non-Destructive Testing (NDT) Audits; VT – Visual MT – Magnetic Particle, PT – Penetrant, UT – Ultrasonic, RT/DR – Radiographic Testing, and Digital Radioscopy. Non-destructive testing (NDT) is a testing and analysis technique used by industry to evaluate the properties of a material, component, structure, or system for characteristic differences or welding defects and discontinuities without causing damage to the original part. NDT is also known as non-destructive examination (NDE), non-destructive inspection (NDI), and non-destructive evaluation (NDE).

-

Welding, brazing & Soldering Audits; GTAW (Gas Tungsten Arc) or TIG, SMAW (Shielded Metal Arc) or Stick, GMAW (Gas Metal Arc) or MIG, FCAW (Flux Core Arc) or Wire Wheel welding. The welding fabrication process joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal).

-

Heat Treatment Audits; Annealing, Case hardening, Precipitation strengthening, Tempering, Carburizing, Normalizing, and Quenching. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material.

-

Chemical Processing Audits. ; Application of Paint & Dry Film Lubricants & Application of Sol-Gel as a Preparation for Paint, Etch Processes (Blue Etch Anodize, Local, Macrostructure, Nital/Temper), Surface Preparation Prior to Metal Bond, Solution Analysis, and Testing in Support of Chemical Processing, Alpha Case Removal and Chemical Milling, Cleanliness Verification, Vacuum Cadmium Deposition or Ion Vapor Deposition of Aluminum, Anodizing, Electroplating, Electroless Plating, Conversion Coating, Acid Cleaning, Descaling, Passivation and Electropolishing, Brush Anodizing and Plating, Stripping of Coatings as a Sub-Contract Process and Pre-Penetrant Etch. Chemical processing (CP) is achieved under Nadcap AC7108 requirements

Aircraft Inspections

-

Federal Aviation Administration (FAA) 100HR & Annual Aircraft Inspections – IA Inspector Available

-

Major Repairs and Alterations Airworthiness inspections

FAA Airmen Certification – A&P Licensing

-

Designated Mechanic Examiner DME –Airframe and Powerplant Oral and Practical TesT

Federal Communications Commission (FCC)

-

FCC Licensed General Radio and Radar Operator – PG/FRN

Page load link

AEROSPACE AND DYNAMIC INDUSTRIES

AEROSPACE AND DYNAMIC INDUSTRIES